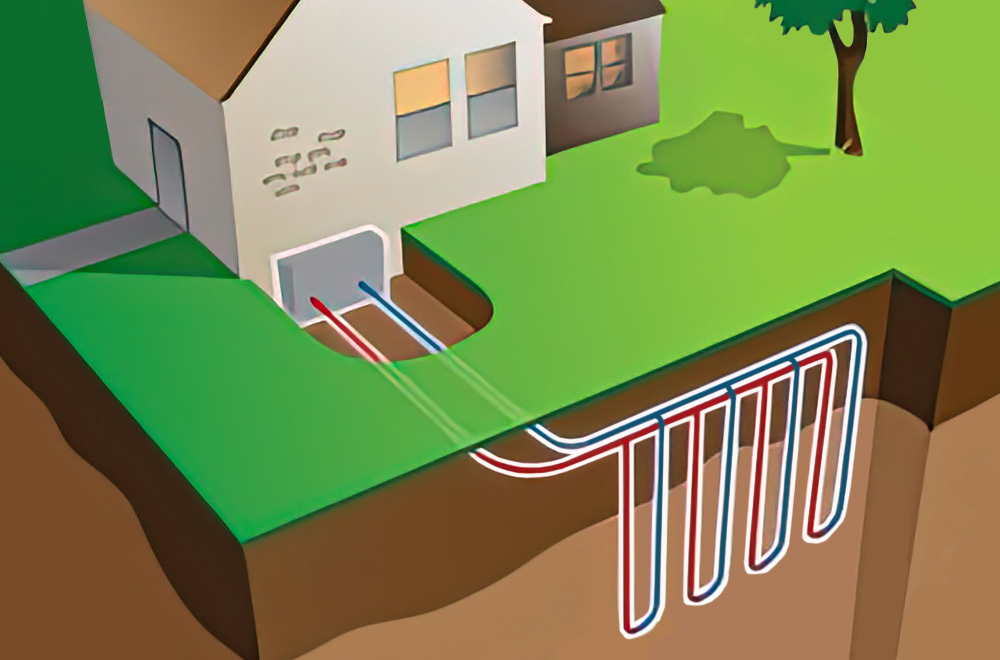

There have been a series of projects at the Rolling Hills Residence that all related to a significant (60%) reduction in CO2 emissions and energy costs. It began with the construction and installation of a geothermal vertical loop ground heat exchange system. The system included 24-hole vertical loops, each hole 400 feet deep, 15 feet apart center to center in the driveway. The geothermal system was sized to replace an existing cooling tower which had been installed to support a central plant heating, ventilation and cooling system. This modification reduced energy needs, CO2 emissions, and equipment noise. It also freed up space for construction of a garden terrace overlooking the tennis court.

One of the existing 25-ton water-cooled chillers was replaced with three 5-ton water-to-water geothermal heat pumps; staged to engage upon demand by the various rooms throughout the property. Two existing natural gas boilers remained as back-up units to the new geothermal system. A 15-ton capacity water-to-water geothermal heat pump was added to maintain the radiant floor heat to the living spaces of the residence and a 5-ton capacity water-to-water geothermal heat pump was added to the bedroom areas to maintain the hot water radiant floor heating system which operated, until recently, almost all year round. In addition, two 2-ton capacity water-to-water geothermal heat pumps were installed to pre-heat the domestic hot water for the residence, further reducing the demand for natural gas. This equipment was connected to the previous central plant condenser water system which now extends to the ground heat exchanger.

The existing condenser water system was then modified to take advantage of the simultaneous operation of all heat pumps in cooling mode and heating mode throughout the house. The “btus” are shared between the heat pumps first, before circulating water to the ground loop. Finally, to better respond to equipment demands and further extend energy efficiency, variable-frequency drive (VFD) motors were added to the system.